Lehm-Terrazzo

Art.-Nr.: 04.100 - 04.599

Fertigmischung für Lehm-Terrazzo Böden, geeignet auch für Fußbodenheizungen. Lehm-Terrazzo greift die traditionelle und edle italienische Boden-Schleiftechnik auf. Das Material ist einzigartig in seiner Optik und Haptik. Die angebotenen Farbtöne machen jeden Boden zum Ereignis. Lehm-Terrazzo ist ein besonderer Design-Werkstoff, auch seine Verarbeitung ist anspruchsvoll. Sprechen Sie uns an!

Produktinformationen lesen » Zur HändlersucheHändlersuche für:

Lehm-Terrazzo

Lehm-Terrazzo

Produktinformationen

Anwendungsgebiet

Terrazzoböden im Innenbereich von Wohngebäuden, als Estrich für Fußbodenheizungen.

Zusammensetzung

Farbige, gemischtkörnige Naturstein-Körnungen 0-16 mm (Überkorn bis 22 mm möglich), Baulehm, farbige Lehme und Tone, Cellulosefasern, Methylcellulose ≤ 1%.

Farbtöne

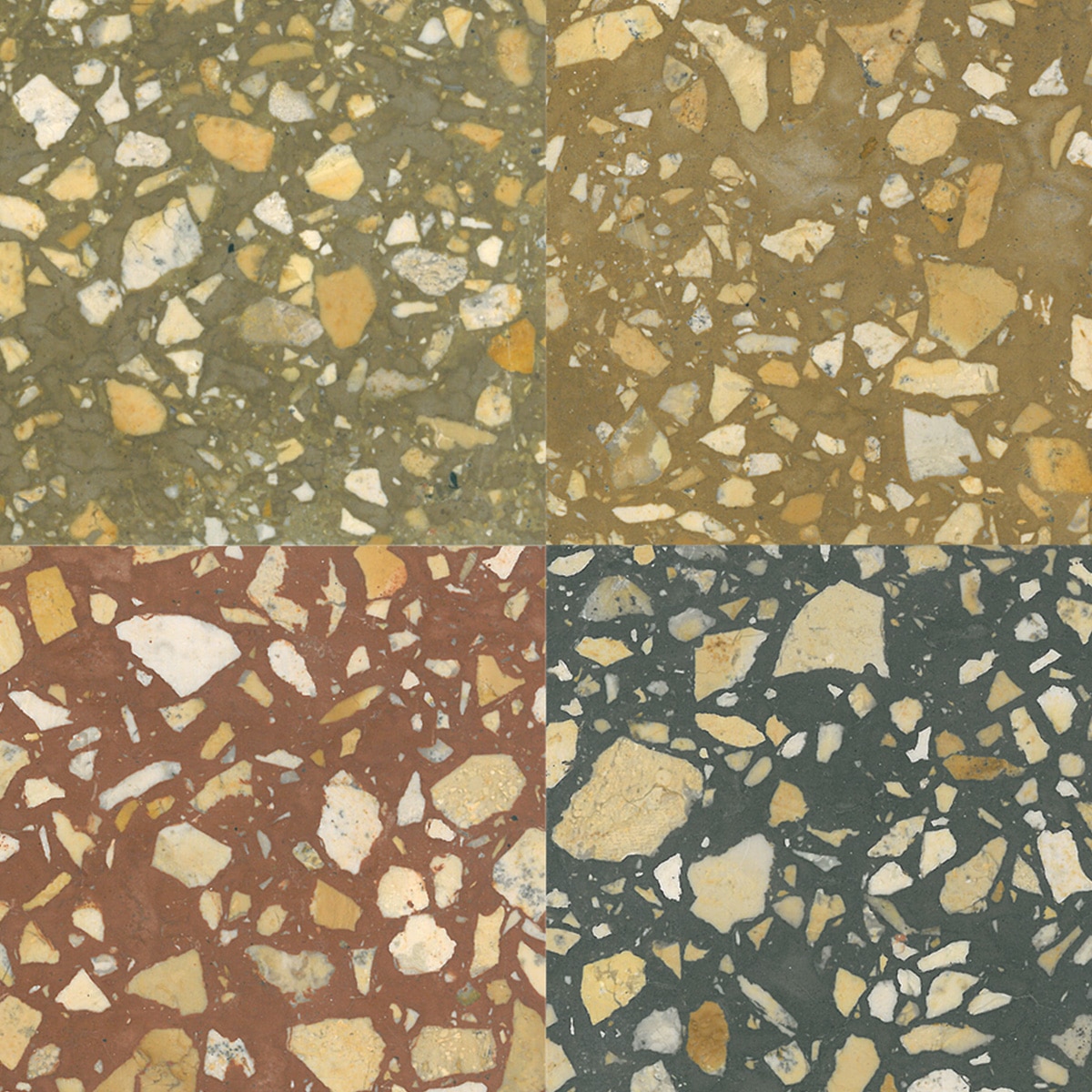

Lehm-Terrazzo ist mit hellgrauer und beiger Körnung sowie einer projektbezogenen Matrix in erdroten, erdgelben, erdgrünen und erdgrauen Tönen lieferbar.

Baustoffwerte

Trockenrohdichte ca. 1.700 kg/m3 (Wärmeleitfähigkeit 1,5 W/mK, µ 5/10)

Lieferform

Projektbezogen erdfeucht angemischt in 1,0 t Big-Bags.

Lagerung

Vor Austrocknung oder Durchfeuchtung durch die Witterung schützen.

Nach der Lieferung, die kurzfristig nach der Herstellung erfolgt, muss Lehm-Terrazzo innerhalb von je nach Witterung 2-4 Wochen verarbeitet werden.

Stand: 03/2021